Vertical Shores

Serialized Tab Data

Home › Hydraulic Shoring Products › Vertical Shores

Vertical Shores

GME® VERTICAL SHORES are designed to prevent cave-ins in the most unstable soil conditions, by supporting the side walls of the trench through the use of hydraulic pressure.

Some of the major benefits of shores are that they are quick, safe and simple to use. They are designed to be installed and removed from the top of the trench 100% of the time.

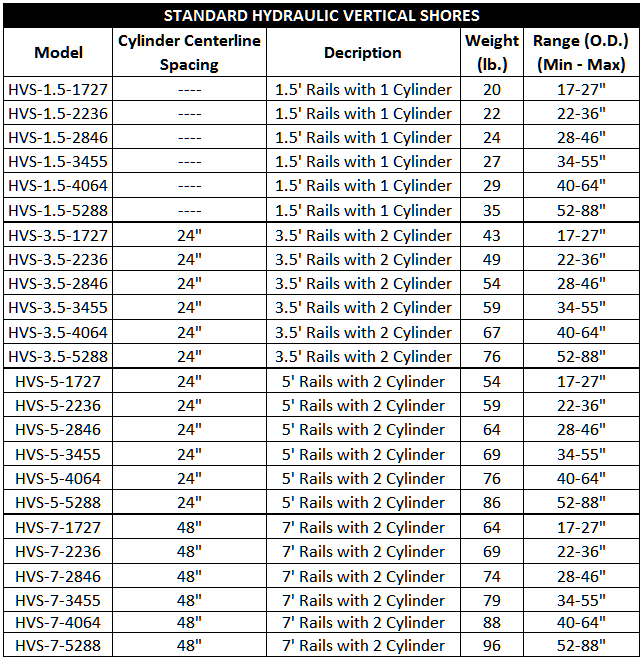

They can be used as spot bracing for repair situations, or can be used for production trenching. GME vertical shores come in standard sizes that range from 18″ to 16′ long. Standard sizes of hydraulic cylinders range from 17″ to 88″ wide. Extensions are available up to 15′ wide.

FEATURES

- Lightweight aluminum alloy construction for both exceptional durability, and easy portability

- Easy to set up

- Can be used with, or without sheeting, according to soil conditions

- Interchangeable components

- Stores compactly

- Cylinders feature over sleeve protection and safety bleed-off port

- All vertical shores are certified by a registered professional engineer to meet OSHA standards

- Complete manufacturer’s tabulated data, and installation/removal procedures are provided

For a quick video on how to install and remove the Vertical Shores System, click here

For a non-You-Tube video on how to install and remove the Vertical Shores System, click here

For the video on how to prime the GME 5-gallon plastic pump can, click here

For a non-youtube video on how to prime the GME 5-gallon plastic pump can, click here

For the video on how to remove and replace the seals on the 5-gallon plastic pump can, click here

Click here to view the metric Standard Hydraulic Vertical Shore chart